The 2024 Marcus Wallenberg Prize is awarded to Prof John Ralph and Prof Wout Boerjan for their dedicated work on understanding of lignin biosynthesis and structural diversity for novel lignin applications. Below you can read the interview with the two laureates.

Interview with John Ralph

1. Could you explain how recent breakthroughs in lignin chemistry, such as depolymerization and functionalization techniques, are enhancing our ability to tailor the properties of lignin-based materials for specific applications?

We are increasingly recognizing that Nature’s flexibility with lignification can be used to our advantage. The discovery of a range of phenolics that may constitute and/or can function as lignin monomers represents a significant breakthrough. Phenolics that can be used by the tree as lignin monomers affect the lignin composition and structure in ways that allow new polymer uses, produce valuable commodity chemicals in previously unimaginably high yields, and/or render delignification to produce cellulose less energetically demanding. Such findings support the early theory of the lignin polymerization mechanism: once the monomer radicals are generated, lignification is directed only by pure chemistry and is not controlled by proteins or enzymes.

The ramifications of this enormously flexible lignification process are being constantly expanded as more and more components from either incomplete monolignol synthesis, products beyond the monolignols, or phenolics from completely outside the traditional lignin biosynthetic pathway, are found in ‘all’ lignins! We are in a time of endlessly exciting discovery.

The worry by some that all this metabolic flexibility only increases the apparent complexity of lignin is mitigated by the recognition that all monomers are incorporated by a single simple mechanism, and because some of the incorporated components can be of extreme value.

2. How might lignin-based materials contribute to reducing plastic pollution and promoting sustainability?

It is now generally accepted that lignin is the largest sustainable source of aromatics on the planet. Currently, we could produce, for example, guaiacylpropanol and/or syringylpropanol in quite high yields (25-50%) from lignin. Some will argue: “But there is no market for these compounds.”The response should be: “But they are not on the market!”

This is the classic ‘chicken and egg’ situation. If we began making large volumes of these beautifully difunctional products available at modest prices, clever chemists, engineers, and technologists would develop processes to make useful products from them that could displace, perhaps even improve on, current offerings.

Some processes would be more sustainable just by their derivation from a renewable resource that is, in principle, carbon-neutral, but emphasis should be on truly recyclable or compostable commodities – whether sustainably produced or not, plastics that are similar to those currently overwhelming the ecosystem need to be phased out.

3. What advancements in lignin chemistry are most promising for creating renewable alternatives to fossil fuel-based products, and how soon might we see these on the market?

We are discovering more and more valuable components in lignins, and have the ability now to engineer novel components into the lignin, potentially making them available on previously unimaginable scale.

Some of these, such as flavonoids, and pharmaceuticals such as paracetamol or its commodity chemical precursor p-aminophenol that is in demand on a more massive scale, could appear rather soon.

Again, some of this is almost a matter of will and impetus. At what point do we realize that the continued use of fossil fuels is completely unsustainable and is degrading our planet’s ecosystem?

Nature can, or can be persuaded to, produce aromatics already functionalized in the way we need them to be. We already have examples of enormously better processes to valuable commodity chemicals from biomass aromatics.

For example, the process from fossil benzene to the popular pain medication paracetamol (acetaminophen, Tylenol®) is ludicrously inefficient, requiring 6 steps and producing side-products. Nature has already done all the work of appropriately functionalizing the component in the tree, a mere THREE simple steps are required to obtain the final product from p-hydroxybenzoates in biomass vs SIX from fossil-fuel benzene!

Right now, however, because of the massive scale of the petrochemical industry, and the enormous subsidies received worldwide, producing paracetamol remains cheaper from fossil fuels, but for how long can we really afford cheap products and the destruction they are causing? Incentives and adoption, with a recognition of the renewable and sustainable nature of biomass, along with increasing knowledge of what biomass has to offer, or could be engineered to offer at the interface of lignin chemistry and plant engineering, could quickly drive adoption of such processes.

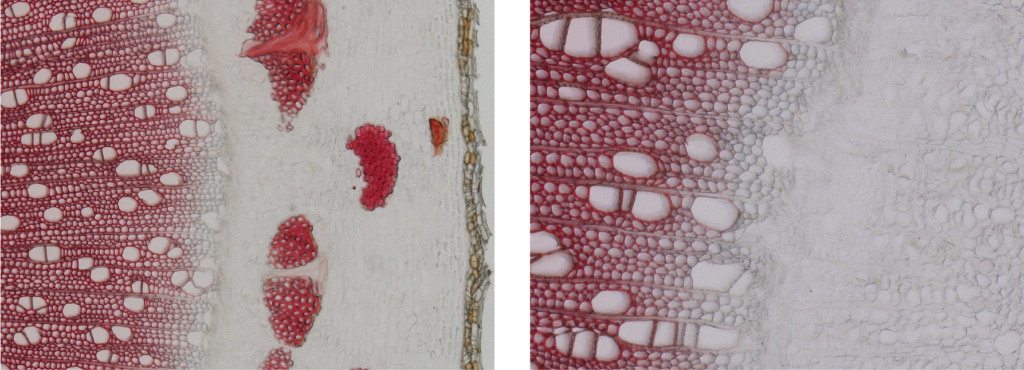

Microscope detail of lignin. Photo: Marta Derba-Maceluch

Interview with Wout Boerjan

1. How has recent progress in genomics and transcriptomics advanced our understanding of the genetic basis of lignin biosynthesis in different plant species, and what implications does this have for the development of tailored lignin traits through selective breeding or genetic engineering?

Progress in genomics and transcriptomics allows us to identify the entire set of lignin biosynthesis genes from different plant species. These genes are typically encoded by multigene families and, in most species, the role of only one or a few of these gene family members has been elucidated.

In most cases, we don’t know yet whether the other gene family members encode proteins with similar activities, or entirely different functions. If they encode enzymes with similar activities, these gene family members may operate in a different cell type or tissue, or at a different stage during wood development, or they may be activated in response to different stress factors, such as leaning of a trunk or branch, or upon attack by a herbivore.

The more we understand the roles of gene family members, the more strategic our engineering strategies will be. With the CRISPR-Cas gene-editing technology, we can now simultaneously alter two or more genes from the same or from different gene families.

2. What role can genetic engineering play in enhancing lignin biosynthesis in plants to produce tailored lignin compositions for specific applications?

There is large variation in lignin amount and composition within a given tree species. Both the amount and composition of lignin are largely controlled by transcription factors that control the expression of the lignin biosynthetic genes.

Once we have a have better understanding of these transcriptional networks, we can tailor lignin amount and composition.

But lignin composition can also be modified by altering the expression of the genes encoding the enzymes of the lignin biosynthesis pathway, e.g. by overexpression, downregulation, or even by fully abolishing the expression of these genes. It is even possible to make lignin structures that are new to nature, by expressing genes required for the biosynthesis of compounds that have the propensity to copolymerize into the lignin polymer. For example, by expressing two genes necessary for the biosynthesis of the coumarin scopoletin, we have been able to engineer plants that incorporate scopoletin into the lignin polymer, thereby rendering the woody biomass more susceptible to alkaline pretreatments.

The more we unravel these biosynthesis pathways, the more possibilities emerge to tailor lignin properties for specific applications, ranging from chemical pulping to reductive or oxidative catalytic fractionation, or processes to clip-off valuable metabolites from the lignin fraction.

3. As we explore lignin biosynthesis pathways, what are the key challenges and ethical considerations in harnessing this knowledge to develop novel lignin-based materials?

Although we can modify lignin structure in plants, it remains difficult to predict whether the properties of the new lignin polymer will still accomodate the biological functions of lignin, such as supporting the plant, allowing transport of water and solutes through the vascular system, and defending the plant against biotic and abiotic stresses.

Similar to conventional trait improvement through classical breeding, engineered plants with different lignin compositions will need to be evaluated for these biological properties, preferentially in field trials that allow the tree to grow for a full rotation, and at different locations with contrasting environments.

Evaluating plant growth in a greenhouse will not be sufficient.

4. With increasing interest in genetic modification, what are the potential benefits and risks associated with engineering plants to produce lignin with altered properties?

The benefits are very obvious. Lignin engineering promises major improvements in several field of society. Most importantly, we contend that lignin engineering can help facilitate the transition from a fossil-based to a bio-based economy.

For example, reducing the amount of lignin facilitates chemical pulping, i.e., reduces chemicals usage and increases pulp yield from a given amount of wood, thereby reducing pressure on land for plantation forestry.

For processes such as reductive catalytic fractionation, lignin engineering allows for making lignin polymers simpler, i.e., making them more homogeneous in structure such that the chemical depolymerization yields higher amounts of specific building blocks for the chemical industries.

Engineering lignin or the bonds between lignin and hemicellulose can facilitate the separation of the carbohydrate fraction (cellulose and hemicellulose) from the lignin fraction. The carbohydrates can then be enzymatically saccharified to primary sugars for fermentation to useful products for society, such as building blocks for bioplastics, detergents or bioethanol.

In other words, lignin engineering allows industry to deconstruct woody biomass more efficiently into chemical building blocks that will feed the bio-economy, rather than relying on fossil resources.